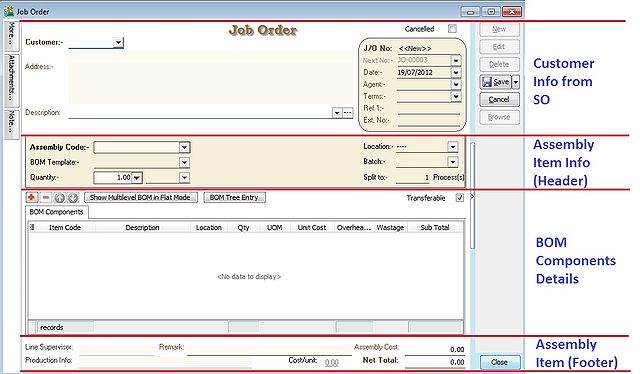

Menu: Production | Job Order...

Introduction

Sales coordinator usually will input the Sales Order (SO) based on the customer PO received. The stock products will be updated into the system as ordered qty.

How much of the materials/components required to meet the products ordered by customer? This question raised by the Material Planning department. Therefore, the Job Order takes place as the order to be input after Sales Order. It will planned the materials/components required based on the qty ordered from Sales Order. When products produce out, basically you have to transfer the Job Order to Stock Assembly to commit on the stock on hand.

IMPORTANT:

It is required the Job Order module. For more information about price, please refer to our sales personal.

Create New Job Order

- CLICK on NEW button and SELECT the Customer.

Customer Info from SO : Basically, the customer and others information copy from SO.

Assembly Item Info (Header & Footer) : Assembly item transferred from SO. It will determine the BOM Components required and the assembly unit cost.

BOM Components Details : Total components quantity requirement to meet the total output.

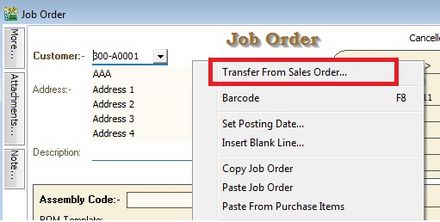

JO Transfer From SO

- RIGHT CLICK on Job Order (Title).

- CLICK on Transfer From Sales Order in the small menu.

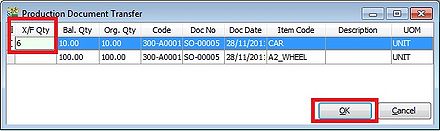

Document Transfer (SO --> JO)

- Pick the item from SO list.

- INPUT X/F qty wish to transfer into JO.

- CLICK OK button to proceed next.